How much K-Meta to water do I need to make a sanatizing solution? I want to make some for a squirt bottle for sanatizing things like spoons, thiefs, hydros, etc without having to mix a new gallon of Easy Clean or 1 step every time I need it. I wasting way too much.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

K-Meta Sanatizing Solution???

- Thread starter JohnnyK68

- Start date

Help Support Winemaking Talk - Winemaking Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

JohnnyK68,

When I started making wine, I purchased the K-meta in 2 oz bottles, but I kept having to go buy more and more, so I started buying it in larger quantities, but kept one 2 oz bottle to measure out the amount for a gallon of solution. Works great!

When I started making wine, I purchased the K-meta in 2 oz bottles, but I kept having to go buy more and more, so I started buying it in larger quantities, but kept one 2 oz bottle to measure out the amount for a gallon of solution. Works great!

$213.50 ($213.50 / Count)

Wine Ingredient Kit - En Primeur Winery Series - South African Sauvignon Blanc

Bridgeview Beer and Wine Supply

$129.00 ($129.00 / Count)

Cru International - Washington Merlot Style Wine Ingredient Kit

Home Brew Ohio

$14.80

$24.00

The Geography of Wine: How Landscapes, Cultures, Terroir, and the Weather Make a Good Drop

Amazon.com

$155.96 ($155.96 / Count)

Winexpert Revelation Napa Cabernet Sauvignon 3 Gallon (Limited) Wine Ingredient Kit

Discount Hydroponics LLc

$29.99 ($15.00 / Count)

$41.80 ($20.90 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$29.95 ($0.00 / Count)

$39.95 ($0.00 / Count)

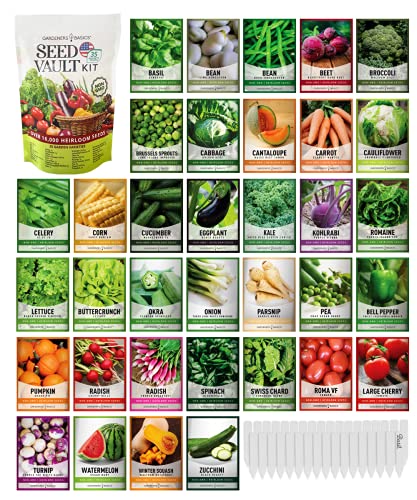

Survival Vegetable Seeds Garden Kit Over 16,000 Seeds Non-GMO and Heirloom, Great for Emergency Bugout Survival Gear 35 Varieties Seeds for Planting Vegetables 35 Free Plant Markers Gardeners Basics

Home and Garden Meadows

$7.90 ($0.20 / Count)

40+ Grape Seeds (Mixed): Grow Your Own Vines (Heirloom, Non-GMO)

SEEDSOFSTRENGTH

$9.99

YIJIAGUO 50 PCS Plant Support Clips, 2024 Tomato Vine Clips, Plastic Garden Trellis Clips for Grape Cucumber Flower Vegetables Climbing Plants, Green

changshaqianjunkejiyouxiangongsi

$22.99

$40.00

The Sommelier's Atlas of Taste: A Field Guide to the Great Wines of Europe

Amazon.com

$169.50 ($169.50 / Count)

Wine Ingredient Kit - CRU SELECT Australia Style Chardonnay

Bridgeview Beer and Wine Supply

smurfe

Senior Member

- Joined

- Jun 20, 2005

- Messages

- 3,625

- Reaction score

- 16

I buy it in the one pound bag. If George sold 5 pound bags I would buy it like that. I put the powder in a Glad "Tupperware" bowl with a lid and keep a plastic measuring spoon in it. Grab the bowl and scoop out what I need.

I use the Na-Meta instead of the K-Meta. It is cheaper and supposedly a bit more potent. I do have a 2 oz packet of K-Meta I use to add the extra 1/4 tsp to batches though. What I do for the spray bottles is to make up a gallon or two to sanitize my equipment for a batch. I then fill my spray bottles and then go about my business.

When I am done I snap a lid on the bucket with the bulk solution for use next time. It will keep for quite a while. Longer than most think. I opened and dumped a bucket of it that was well over 6 months old when I moved. It still knocked me over with the smell when I opened the bucket.I wouldn't of used it but it was still strongly emitting sulfite's.

Smurfe

I use the Na-Meta instead of the K-Meta. It is cheaper and supposedly a bit more potent. I do have a 2 oz packet of K-Meta I use to add the extra 1/4 tsp to batches though. What I do for the spray bottles is to make up a gallon or two to sanitize my equipment for a batch. I then fill my spray bottles and then go about my business.

When I am done I snap a lid on the bucket with the bulk solution for use next time. It will keep for quite a while. Longer than most think. I opened and dumped a bucket of it that was well over 6 months old when I moved. It still knocked me over with the smell when I opened the bucket.I wouldn't of used it but it was still strongly emitting sulfite's.

Smurfe

I just dumped some k-meta that I had for three months that smelled alot

stronger than usual for some reason. I used the recommended 3 tbs per

gallon and when I opened it yesterday I almost fell over it was so

strong. When in dought, dump it out!

stronger than usual for some reason. I used the recommended 3 tbs per

gallon and when I opened it yesterday I almost fell over it was so

strong. When in dought, dump it out!

PeterZ

Senior Member

- Joined

- Nov 2, 2006

- Messages

- 1,290

- Reaction score

- 1

Wade and Smurfe, as the weather gets warmer the SO2 in the headspace of whatever you store the solution in will have a higher concentration of SO2. The SO2 exists in the solution in equilibrium with H2SO3. (SO2 + H2O --> H2SO3) As temperature increases, the solubility of SO2 goes down, forcing the SO2 into the air. That's why it smelled stronger.

A (K/Na) meta solution can't really go bad. It loses potency by reacting with oxygen, turning from H2SO3 to H2SO4, which is useless from our perspective. The only thing that can "spoil" the solution is a bacteria called Desulfovibrio sp., an anaerobic bacteria that uses the SO4-- ion to get oxygen for respiration, releasing S-- (sulfide). If you don't smell H2S (rotten egg smell), then the solution is still good.

Desulfrovibrio sp. is virtually unheard of in municipal tap water. It is only a potential concern in untreated well water. Even then I would be surprized to see it, as it usually grows under gunky deposits. It is a major problem in industry, as S-- will pit through most stainless steels in a heartbeat.

A word about stainless steel. It is stain "less," not stain "free." Stainless steel can and does corrode under the correct environments. We use primarily 304SS (UNS 30400), one of the lower grades of stainless. As long as the liquid is oxygenated the O2 in solution reacts with the chromium in the SS to form a very tough chrome/iron oxide film on the surface of the steel. Under anaerobic (no O2) conditions that film cannot reform if damaged, and pitting corrosion will occur.

This is not really a problem for us, as using a SS tank for bulk aging there is nothing to break the film. Major problem in industry, however, to the tune of >$13 billion per year. (Can you tell this is one of my specialities in my chemist days?)

A (K/Na) meta solution can't really go bad. It loses potency by reacting with oxygen, turning from H2SO3 to H2SO4, which is useless from our perspective. The only thing that can "spoil" the solution is a bacteria called Desulfovibrio sp., an anaerobic bacteria that uses the SO4-- ion to get oxygen for respiration, releasing S-- (sulfide). If you don't smell H2S (rotten egg smell), then the solution is still good.

Desulfrovibrio sp. is virtually unheard of in municipal tap water. It is only a potential concern in untreated well water. Even then I would be surprized to see it, as it usually grows under gunky deposits. It is a major problem in industry, as S-- will pit through most stainless steels in a heartbeat.

A word about stainless steel. It is stain "less," not stain "free." Stainless steel can and does corrode under the correct environments. We use primarily 304SS (UNS 30400), one of the lower grades of stainless. As long as the liquid is oxygenated the O2 in solution reacts with the chromium in the SS to form a very tough chrome/iron oxide film on the surface of the steel. Under anaerobic (no O2) conditions that film cannot reform if damaged, and pitting corrosion will occur.

This is not really a problem for us, as using a SS tank for bulk aging there is nothing to break the film. Major problem in industry, however, to the tune of >$13 billion per year. (Can you tell this is one of my specialities in my chemist days?)

Thanks Pet as I was curious as this was a typical batch at a typical

duration. Usually Im finishing it up about this time but this gallon

was still half full because I cut down on making wines due to the cold

temps in the house so I had more left.

duration. Usually Im finishing it up about this time but this gallon

was still half full because I cut down on making wines due to the cold

temps in the house so I had more left.

smurfe

Senior Member

- Joined

- Jun 20, 2005

- Messages

- 3,625

- Reaction score

- 16

geocorn said:Ok, smurfe, you win.I can and will get the 5 lb. size of the sodium metabisulfite, just for you!!!!!!!1

WOO-HOO! I am ready to get things fired back up after moving. I just noticed I am low after I started the Mist and the Port kit this last week. Still have another Port to get going. Dang, I guess I have already started back up. I am really looking forward to trying one of those big Mosti kits.

Smurfe

geocorn said:Ok, smurfe, you win.I can and will get the 5 lb. size of the sodium metabisulfite, just for you!!!!!!!1

Cool...I will be buying some of that also!

redwineleo

Member

- Joined

- Oct 26, 2005

- Messages

- 69

- Reaction score

- 0

PeterZ: So if I keep my solution in a 1 gallon glass jug under airlock (also a K-Meta solution) it should keep for a very long time, correct?

NorthernWinos

Senior Member

- Joined

- Nov 7, 2005

- Messages

- 5,933

- Reaction score

- 8

I keep mine in a gallon jug...not with an airlock but with a cap...should it have an airlock???

NW,

I bought a few gallons of bottled water for a mead I made last year and have been using the jug for my meta solution ever since. I only use a cap and I usually keep the solution for 6 months and dump it. My solution begins to gather small pieces of "stuff" after a while and I get worried and dump it. It is most likely still good, but with floaties there, I cant stand it!

I bought a few gallons of bottled water for a mead I made last year and have been using the jug for my meta solution ever since. I only use a cap and I usually keep the solution for 6 months and dump it. My solution begins to gather small pieces of "stuff" after a while and I get worried and dump it. It is most likely still good, but with floaties there, I cant stand it!

I do not use an airlock. I have to replace the plastic gallon jugs

every once in awhile as the plastic gives way eventually I guess due to

the chems. I have replced it with glass now as it gave way the other

day after I just filled it with fresh meta and found it 3/4 empty the

next day and meta all over the shelf. Good news is the shelf is now

sterile!

every once in awhile as the plastic gives way eventually I guess due to

the chems. I have replced it with glass now as it gave way the other

day after I just filled it with fresh meta and found it 3/4 empty the

next day and meta all over the shelf. Good news is the shelf is now

sterile!

NorthernWinos

Senior Member

- Joined

- Nov 7, 2005

- Messages

- 5,933

- Reaction score

- 8

I thought it was suppose to be a tight cap...will continue what I am doing.

Boy, that stuff eats your plastic jugs....

Boy, that stuff eats your plastic jugs....

Similar threads

- Replies

- 20

- Views

- 947

- Replies

- 31

- Views

- 3K

- Replies

- 16

- Views

- 632

![[Upgraded] 9Pcs Tree Root Growing Box with Drain Holes, Half Transparent Plant Rooting Propagation Ball & Metal Core Twist Ties, for Fast Propagation Plants (Size M)](https://m.media-amazon.com/images/I/514MWQxtWOL._SL500_.jpg)