NorCal

Senior Member

I spend good money for grapes, yeast, mlf and put hours of effort in order to make the best wine that I can. I pay a premium for professional looking labels, as I want my wine to look as good as it tastes. It comes down to the final step; putting the label on the bottle. Nothing say amateur more than uneven or crooked labels on the bottle.

Since I bottle 300 or more bottles at a time, I have friends and family assist in the process and I found that setting up different work stations/jobs worked the best. I wanted a fixture that made it real easy for a helper to put the label on the bottle straight and in the same place every time.

I was trying to figure out a way to use a low cost laser when an engineer at worked said you need something like a barcode scanner. Bingo! $14 from eBay, another $14 for a foot switch from harbor freight, an extra USB charger from an old iPhone and some leftover wood and I had the makings for the laser label alignment fixture.

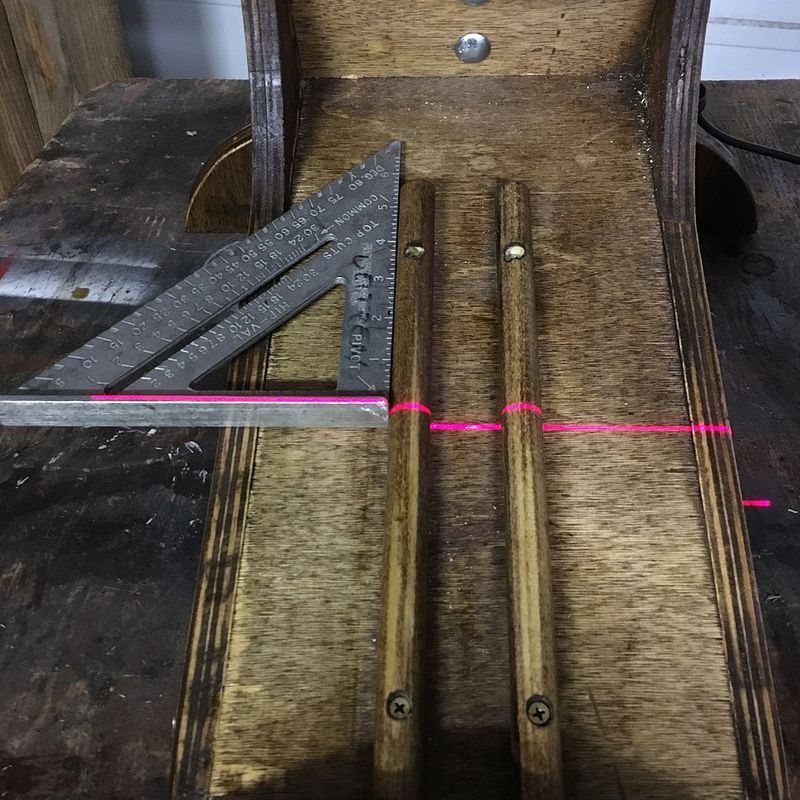

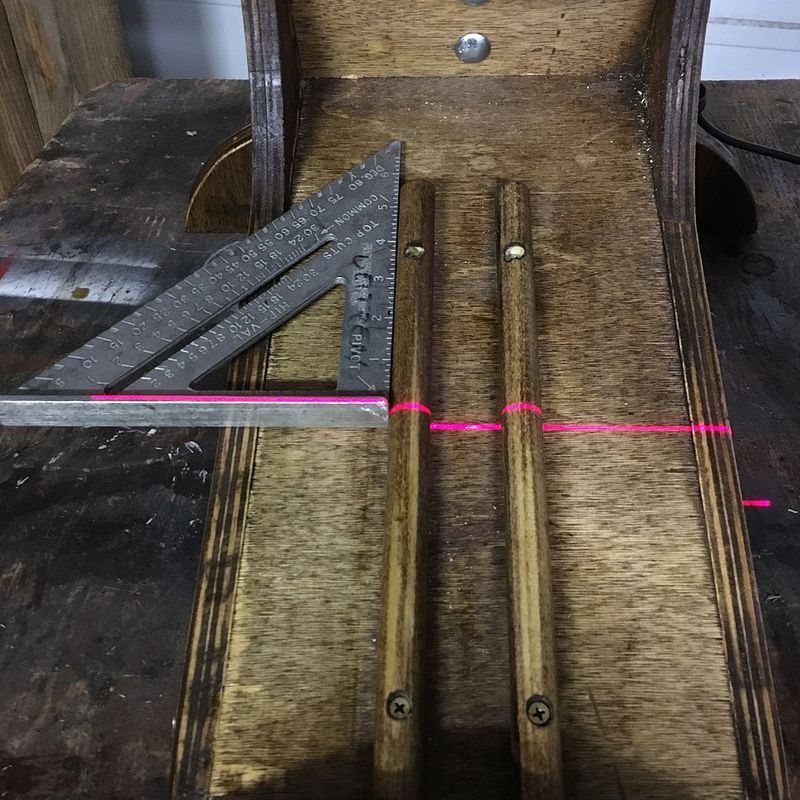

Two dowels keep the bottle centered.

The barcode reader normally times out after 3 or 4 seconds, but I was able to program it to stay on continuously. The foot switch keeps the hands free to handle the bottles.

Built in adjustments for the location of the label on the bottle as well as the angle of the bottle to the operator.

I haven't had the need to run a barrels worth of bottles through it yet, but in my trials it takes but a few seconds to get a label on straight and consistently positioned on the bottle.

Since I bottle 300 or more bottles at a time, I have friends and family assist in the process and I found that setting up different work stations/jobs worked the best. I wanted a fixture that made it real easy for a helper to put the label on the bottle straight and in the same place every time.

I was trying to figure out a way to use a low cost laser when an engineer at worked said you need something like a barcode scanner. Bingo! $14 from eBay, another $14 for a foot switch from harbor freight, an extra USB charger from an old iPhone and some leftover wood and I had the makings for the laser label alignment fixture.

Two dowels keep the bottle centered.

The barcode reader normally times out after 3 or 4 seconds, but I was able to program it to stay on continuously. The foot switch keeps the hands free to handle the bottles.

Built in adjustments for the location of the label on the bottle as well as the angle of the bottle to the operator.

I haven't had the need to run a barrels worth of bottles through it yet, but in my trials it takes but a few seconds to get a label on straight and consistently positioned on the bottle.

![[Upgraded] 9Pcs Tree Root Growing Box with Drain Holes, Half Transparent Plant Rooting Propagation Ball & Metal Core Twist Ties, for Fast Propagation Plants (Size M)](https://m.media-amazon.com/images/I/514MWQxtWOL._SL500_.jpg)