Or, as they used to say before smart phones: "A man with one watch knows what time it is. A man with two is never sure."

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

So how much alcohol is REALLY in my wine?

- Thread starter BigDaveK

- Start date

Help Support Winemaking Talk - Winemaking Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

anybody who is “going for it” to make a new wine should take the hydrometer readings with a grain of salt, , , , ie what is the expected “normal“ error by moving from a sucrose solution on the lab bench to an uncalibrated mixture of soluble solids.

soluble solids is important if moving from a juice in a dry season versus a wet season and always when moving from crop to crop to crop. ,,, I running apple juice technically should not use the same hydrometer as I would with grape juice, ,,, but it is pretty good to show when there isn’t more change so I won’t get expensive hydrometers.

The only real way to know what alcohol you have made is to have a lab test run.

The accurate way to know how much reducing sugar is in your must is to run the lab test.

soluble solids is important if moving from a juice in a dry season versus a wet season and always when moving from crop to crop to crop. ,,, I running apple juice technically should not use the same hydrometer as I would with grape juice, ,,, but it is pretty good to show when there isn’t more change so I won’t get expensive hydrometers.

The only real way to know what alcohol you have made is to have a lab test run.

The accurate way to know how much reducing sugar is in your must is to run the lab test.

? which sugar ? remember glucose is more fermentable than fructoseOne thing we learned in beginning chemistry is that every measurement is an approximation, which can be expressed at +/- the margin of error. All we need is a measurement that is accurate enough for our purposes. So a tape measure is good enough for most household projects, but for some engineering projects you might need an extremely accurate micrometer. Even if I had a micrometer, I would not use it for building a workbench. I suppose that the only 100% accurate measurement of sugar would be to find a way to count the sugar molecules.

This has been a great discussion. Although it has advanced my knowledge quite a bit, it's also reinforced my practice of using the formula I believe to be the closest to reality, and not worrying about it. I'm not expecting pinpoint accuracy, and this expectation is being met.

However, I am taking another look at the ABV calculation formulas to see if I should change. Once that is done, I'll go with whatever looks best, which may be the current formula.

However, I am taking another look at the ABV calculation formulas to see if I should change. Once that is done, I'll go with whatever looks best, which may be the current formula.

winemanden

Senior Member

At the laboratory where I worked there was a contractor laying paving slabs. One of the Engineering scientists stood looking at him work.One thing we learned in beginning chemistry is that every measurement is an approximation, which can be expressed at +/- the margin of error. All we need is a measurement that is accurate enough for our purposes. So a tape measure is good enough for most household projects, but for some engineering projects you might need an extremely accurate micrometer. Even if I had a micrometer, I would not use it for building a workbench. I suppose that the only 100% accurate measurement of sugar would be to find a way to count the sugar molecules.

However, this rabbit hole is interesting. It appeals to my inner nerd.

"Something wrong?" asked the contractor.

"Nothing wrong", replied the scientist. "I like to see somebody doing a good accurate job. We have to work to 10,000th of an inch here".

"You'd be no good doing this then mate", said the contractor. "On this job you've got to be spot on!"

anybody who is “going for it”

I disagree that the dissolved sugar is "by far and away" the principal contributor to SG. UC Davis suggests assuming an SG equivalent of .021 of non-fermentable solids in a must. 20-25% is not insignificant. And it's surprisingly close to the number I mentioned in my message #36.what is the expected “normal“ error by moving from a sucrose solution on the lab bench to an uncalibrated mixture of soluble solids.

soluble solids is important if moving from a juice in a dry season versus a wet season and always when moving from crop to crop to crop. ,,, I running apple juice technically should not use the same hydrometer as I would with grape juice, ,,, but it is pretty good to show when there isn’t more change so I won’t get expensive hydrometers.

Yes, wine yeast is definitely glucophilic. Given a choice it picks glucose over fructose every time. Though the glucose/fructose ratio is different for each yeast strain. I believe the the rule of thumb is that if there's residual sugar after fermentation there's 10 times more fructose than glucose. On a personal note, I've had a couple dessert wines with residual sugar. I definitely prefer the sweetness of the fructose over the sweetness from back sweetening.? which sugar ? remember glucose is more fermentable than fructose

And I have an experience from this week to add to the discussion -

I currently have a raspberry dessert wine, step fed, in the works. I used 3 popular approximations to "calculate" ABV - cumulative change in SG, multiplying by 1.32, and dividing by 7.36. The results were 20.9%, 21.12%, and 21.74%. It's still fermenting like crazy and I'm getting daily drops of at least .005. That means it's using a little over 2 oz of sugar daily for ethanol production. I call bullsh*t on my own wine. A still visually active fermentation with supposedly that much alcohol? I don't believe it.

BTW, it tastes really good. I tried a cool fermentation this time, ambient temp around 58F.

This issue occurred to be earlier. If we can assume that most/all of the other dissolved solids remain dissolved, then the change in SG can give us a good idea of how much sugar was consumed by the yeast, and we can estimate ABV. If some of the solids are suspended rather than dissolved, it might be good to run the sample through a coffee filter before measuring OG.I disagree that the dissolved sugar is "by far and away" the principal contributor to SG. UC Davis suggests assuming an SG equivalent of .021 of non-fermentable solids in a must. 20-25% is not insignificant.

$213.50 ($213.50 / Count)

Wine Ingredient Kit - En Primeur Winery Series - South African Sauvignon Blanc

Bridgeview Beer and Wine Supply

$169.50 ($169.50 / Count)

Wine Ingredient Kit - CRU SELECT Australia Style Chardonnay

Bridgeview Beer and Wine Supply

$155.96 ($155.96 / Count)

Winexpert Revelation Napa Cabernet Sauvignon 3 Gallon (Limited) Wine Ingredient Kit

Discount Hydroponics LLc

$22.99

$40.00

The Sommelier's Atlas of Taste: A Field Guide to the Great Wines of Europe

Amazon.com

$129.00 ($129.00 / Count)

Cru International - Washington Merlot Style Wine Ingredient Kit

Home Brew Ohio

$7.90 ($0.20 / Count)

40+ Grape Seeds (Mixed): Grow Your Own Vines (Heirloom, Non-GMO)

SEEDSOFSTRENGTH

$9.99

YIJIAGUO 50 PCS Plant Support Clips, 2024 Tomato Vine Clips, Plastic Garden Trellis Clips for Grape Cucumber Flower Vegetables Climbing Plants, Green

changshaqianjunkejiyouxiangongsi

$14.80

$24.00

The Geography of Wine: How Landscapes, Cultures, Terroir, and the Weather Make a Good Drop

Amazon.com

$29.95 ($0.00 / Count)

$39.95 ($0.00 / Count)

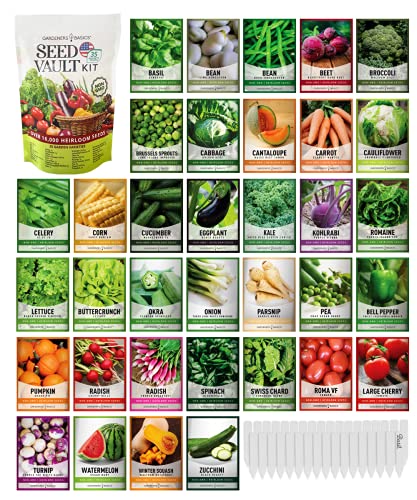

Survival Vegetable Seeds Garden Kit Over 16,000 Seeds Non-GMO and Heirloom, Great for Emergency Bugout Survival Gear 35 Varieties Seeds for Planting Vegetables 35 Free Plant Markers Gardeners Basics

Home and Garden Meadows

$29.99 ($15.00 / Count)

$41.80 ($20.90 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

Agree with the above: If the OG contains nonfermentables it makes sense that they would show up in the final SG, therefore, the reduction in SG would be from fermentable sugars and represent approximate alcohol production and account for not all fermentations completing at a SG less than 1.0.

My thought is that the non-fermentables settle during fermentation and that's why we see mostly .990 rather than 1.000+. Do they contribute anything beneficial to the wine? Don't know.

There are moments when I miss the innocent time of just plain ol' throwing things in a bucket.

There are moments when I miss the innocent time of just plain ol' throwing things in a bucket.

Stop thinking. Doing that was the best decision I made in my life.There are moments when I miss the innocent time of just plain ol' throwing things in a bucket.

- there are a variety of non sugar water soluble molecules, example northern/ wild grapes, current and grapefruit have a high percent acid, pear juice has sugar alcohol, gum Arabic has a polysaccharide, honey has higher sugars that don’t ferment, amino acids get incorporated into cells but don’t ferment, normal fermentations leave 1.5 to 2 gm/ liter of unusual reducing sugars as arabinose, xylose, pentodes, and if I am on the lab bench I could add lactose ( milk sugar) . . . . ie lots of molecules are water soluble and don’t ferment into alcohol.My thought is that the non-fermentables settle during fermentation and that's why we see mostly .990 rather than 1.000+. Do they contribute anything beneficial to the wine?

- alcohol has a lower density than water, therefore the more alcohol produces lower density.

- some yeast products as glycerol are more dense therefore this would increase SG above 1.000

- salts are the standard lab method to calibrate a hydrometer, and of course every organic acid ion comes along with an alkali salt

The system is a mixture, it will vary from fermentation to fermentation. ,,,, >>>> the commercial way to say one has a legal label is to measure the ABV

Last edited:

I know what you're saying.- there are a variety of non sugar water soluble molecules, example northern/ wild grapes, current and grapefruit have a high percent acid, pear juice has sugar alcohol, gum Arabic has a polysaccharide, honey has higher sugars that don’t ferment, amino acids get incorporated into cells but don’t ferment, normal fermentations leave 1.5 to 2 gm/ liter of unusual reducing sugars as arabinose, xylose, pentodes, and if I am on the lab bench I could add lactose ( milk sugar) . . . . ie lots of molecules are water soluble and don’t ferment into alcohol.

- alcohol has a lower density than water, therefore the more alcohol produces lower density.

- some yeast products as glycerol are more dense therefore this would increase SG above 1.000

- salts are the standard lab method to calibrate a hydrometer, and of course every organic acid ion comes along with an alkali salt

The system is a mixture, it will vary from fermentation to fermentation. ,,,, >>>> the commercial way to say one has a legal label is to measure the ABV

Every single ferment is unique. The entire process fascinates me and I have a boatload of questions - isn't that what a student is supposed to do?

I can read, I can get help from this wonderful community, and I can "do"...can't beat experience.

And I'm still trying to find out how much sugar is used specifically for reproduction.

No can do. It's a curse.Stop thinking.

Dave, I took your question through this tunnel… so, it’s more than reproduction of course, it’s simply all of the yeast cells metabolic capacity throughout life, including reproductive efforts / budding, etc…

I was also thinking you could take an OG that is strained of solids and a similarly strained FG and get a lab test of sugar content. That could give you a cleaner idea of sugar content. Use the same sample with a hydrometer to see any appreciable differences.

Sugar (nutrient) use by yeast will depend on strength of the colony, size of the colony, reproductive ability and activity, etc… I imagine the biggest factor would be colony size, which is measurable, multiplied by energy requirement, over time. Since colony size is variable to time and other factors, it would probably have to be measured several times. Once you have this factor, you could subtract your results from the overall (OG) to get a more accurate picture.

I suppose you could also align lab tested sugar content (from OG to FG) to a lab tested alcohol content on a graph to see the associations through a fermentation cycle. Subtract the sugars used from yeast colony size on the same graph to see what you’re seeking?

What Does Yeast Need To Reproduce

Reproductive potential of yeast cells depends on overall action of interconnected changes in central carbon metabolism, cellular bio synthetic capacity and proteostasis.

I was also thinking you could take an OG that is strained of solids and a similarly strained FG and get a lab test of sugar content. That could give you a cleaner idea of sugar content. Use the same sample with a hydrometer to see any appreciable differences.

Sugar (nutrient) use by yeast will depend on strength of the colony, size of the colony, reproductive ability and activity, etc… I imagine the biggest factor would be colony size, which is measurable, multiplied by energy requirement, over time. Since colony size is variable to time and other factors, it would probably have to be measured several times. Once you have this factor, you could subtract your results from the overall (OG) to get a more accurate picture.

I suppose you could also align lab tested sugar content (from OG to FG) to a lab tested alcohol content on a graph to see the associations through a fermentation cycle. Subtract the sugars used from yeast colony size on the same graph to see what you’re seeking?

What Does Yeast Need To Reproduce

Reproductive potential of yeast cells depends on overall action of interconnected changes in central carbon metabolism, cellular bio synthetic capacity and proteostasis.

It seems I can find every single number except the one I want. To reproduce they like oxygen at 5ppm, normal atmospheric pressure would provide 8ppm. Ideal pH is around 4.0-4.5. Temperature 78F. And not too much sugar. Supposedly under those conditions if you started with 10 gr of yeast you would have 150 tons in a week. I imagine you'd need a few tons of sugar to maintain the proper solution.Sugar (nutrient) use by yeast will depend on strength of the colony, size of the colony, reproductive ability and activity, etc… I imagine the biggest factor would be colony size, which is measurable, multiplied by energy requirement, over time. Since colony size is variable to time and other factors, it would probably have to be measured several times. Once you have this factor, you could subtract your results from the overall (OG) to get a more accurate picture.

And as I mentioned, they use 1-2% of their body weight in sugar for fermentation. Why can't I find a similar percentage for reproduction, dammit.

I found a paper from 1951 using differential equations to calculate the size of a yeast colony and the amount of sugar being used. Makes sense using diffy-Q's since the number of yeast is constantly changing. It's a little too old for me, though. Looking for more recent corroboration.

Of course lab tests would be quick but where's the fun in that?

Dave,

Today‘s contribution to the cause…

During 20 days of retentostats cultivation, the specific growth rate gradually decreased from 0.025 h−1 to below 0.001 h−1, while culture viability remained above 80 %. The maintenance requirement for ATP (mATP) was estimated at 0.63 ± 0.04 mmol ATP (g biomass)−1 h−1, which is ca. 35 % lower than previously estimated for anaerobic retentostats.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4912818/

Metabolism in yeast cells can be manipulated by supplying different carbon sources: yeast grown on glucose rapidly proliferates by fermentation, analogous to tumour cells growing by aerobic glycolysis, whereas on non-fermentable carbon sources metabolism shifts towards respiration.

https://genomebiology.biomedcentral.com/articles/10.1186/s13059-016-1101-2

Different energy coupling strategies produces differing yields.

https://academic.oup.com/femsyr/article/12/4/387/670760

https://edisciplinas.usp.br/pluginf...ent/1/PQI5888 - Aula 9 - Yeast Metabolism.pdf

https://fermfacts.com/ferm-facts/the-right-foundation/

Today‘s contribution to the cause…

During 20 days of retentostats cultivation, the specific growth rate gradually decreased from 0.025 h−1 to below 0.001 h−1, while culture viability remained above 80 %. The maintenance requirement for ATP (mATP) was estimated at 0.63 ± 0.04 mmol ATP (g biomass)−1 h−1, which is ca. 35 % lower than previously estimated for anaerobic retentostats.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4912818/

Metabolism in yeast cells can be manipulated by supplying different carbon sources: yeast grown on glucose rapidly proliferates by fermentation, analogous to tumour cells growing by aerobic glycolysis, whereas on non-fermentable carbon sources metabolism shifts towards respiration.

https://genomebiology.biomedcentral.com/articles/10.1186/s13059-016-1101-2

Different energy coupling strategies produces differing yields.

https://academic.oup.com/femsyr/article/12/4/387/670760

https://edisciplinas.usp.br/pluginf...ent/1/PQI5888 - Aula 9 - Yeast Metabolism.pdf

https://fermfacts.com/ferm-facts/the-right-foundation/

winemanden

Senior Member

It's my wine! Skol. As long as it's near enough what I aimed for. Here's mud in you eye. If you're worried about it not keeping, drink it. Cheers.

Is my glass half full or half empty?

Is my glass half full or half empty?

Great info.Dave,

Today‘s contribution to the cause…

During 20 days of retentostats cultivation, the specific growth rate gradually decreased from 0.025 h−1 to below 0.001 h−1, while culture viability remained above 80 %. The maintenance requirement for ATP (mATP) was estimated at 0.63 ± 0.04 mmol ATP (g biomass)−1 h−1, which is ca. 35 % lower than previously estimated for anaerobic retentostats.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4912818/

Metabolism in yeast cells can be manipulated by supplying different carbon sources: yeast grown on glucose rapidly proliferates by fermentation, analogous to tumour cells growing by aerobic glycolysis, whereas on non-fermentable carbon sources metabolism shifts towards respiration.

https://genomebiology.biomedcentral.com/articles/10.1186/s13059-016-1101-2

Different energy coupling strategies produces differing yields.

https://academic.oup.com/femsyr/article/12/4/387/670760

https://edisciplinas.usp.br/pluginf...ent/1/PQI5888 - Aula 9 - Yeast Metabolism.pdfView attachment 98232

View attachment 98234

https://fermfacts.com/ferm-facts/the-right-foundation/

View attachment 98235

I'm taking a brief break from this rabbit hole only to get away from the frustration for a couple days.

I saved the articles you included to read in a couple days.

When you're ready to come back...

FEMS Yeast Research, Volume 3, Issue 2, April 2003, Pages 149–157, impact of brewing yeast cell age on fermentation performance, attenuation and flocculation

The impact of brewing yeast cell age on fermentation performance, attenuation and flocculation

Chris D Powell, David E Quain, Katherine A SmartFEMS Yeast Research, Volume 3, Issue 2, April 2003, Pages 149–157, impact of brewing yeast cell age on fermentation performance, attenuation and flocculation

When you're ready to come back...

The impact of brewing yeast cell age on fermentation performance, attenuation and flocculation

Chris D Powell, David E Quain, Katherine A Smart

FEMS Yeast Research, Volume 3, Issue 2, April 2003, Pages 149–157, impact of brewing yeast cell age on fermentation performance, attenuation and flocculation

A quote from that article: "Aged cells were observed to ferment more efficiently and at a higher rate than mixed aged or virgin cell cultures. Additionally, the flocculation potential and cell surface hydrophobicity of cells was observed to increase in conjunction with cell age."

We old farts just keep getting better and better!

You are no help.When you're ready to come back...

The impact of brewing yeast cell age on fermentation performance, attenuation and flocculation

Chris D Powell, David E Quain, Katherine A Smart

FEMS Yeast Research, Volume 3, Issue 2, April 2003, Pages 149–157, impact of brewing yeast cell age on fermentation performance, attenuation and flocculation

I looked at the article and then did something silly - I did a search for "wine". Came back with 693 articles. Some will be useful, some not. But still...thanks. Thanks a lot. My reading list was already growing exponentially.

Similar threads

- Replies

- 17

- Views

- 1K

- Replies

- 26

- Views

- 3K

- Replies

- 7

- Views

- 2K

- Replies

- 7

- Views

- 886

- Replies

- 7

- Views

- 3K