You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wine pump and degasser

- Thread starter Wade E

- Start date

Help Support Winemaking Talk - Winemaking Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Nov 12, 2005

- Messages

- 15,188

- Reaction score

- 1,213

Valley Vintner is a source of some better filters, but are more money.

http://valleyvintner.com/Merchant2/merchant.mv?Screen=PROD&Product_Code=WE-30-4860&Category_Code=PF

If you buy one, check the brand on the label and then look up a cheaper source online. I don't remember who I found right now.

I just looked up the one Wade listed. Ouch!

http://valleyvintner.com/Merchant2/merchant.mv?Screen=PROD&Product_Code=WE-30-4860&Category_Code=PF

If you buy one, check the brand on the label and then look up a cheaper source online. I don't remember who I found right now.

I just looked up the one Wade listed. Ouch!

gaudet

Senior Member

- Joined

- Jun 21, 2008

- Messages

- 1,840

- Reaction score

- 3

http://www.advancedwaterfilters.com/filter-products/sediment-filter-dual-gradient-density-25-1-micron-20-x-45.html

Yep $36 a filter........... that ends up being a little over a dollar a bottle for a 6 gallon batch.

Yep $36 a filter........... that ends up being a little over a dollar a bottle for a 6 gallon batch.

Thanks for the ideas. I actually found this one which is a little cheaper in shipping than micronfiltercartridges.

www.H2ofilters.com

Now I need to pick up some fittings for the canister and some hose, another long racking caneand I am off to the races!

www.H2ofilters.com

Now I need to pick up some fittings for the canister and some hose, another long racking caneand I am off to the races!

$23.98

$40.00

The Sommelier's Atlas of Taste: A Field Guide to the Great Wines of Europe

WeBook

$9.99 ($0.10 / Count)

$13.29 ($0.13 / Count)

CIMAXIC 100 Pcs Reusable Grape Paper Grow Bags Nursery Bags for Fruits Vegetables Ideal for Garden Use and Plant Growth

Ruizieng

$7.90 ($0.20 / Count)

40+ Grape Seeds (Mixed): Grow Your Own Vines (Heirloom, Non-GMO)

SEEDSOFSTRENGTH

$14.80

$24.00

The Geography of Wine: How Landscapes, Cultures, Terroir, and the Weather Make a Good Drop

Amazon.com

$129.00 ($129.00 / Count)

Cru International - Washington Merlot Style Wine Ingredient Kit

Home Brew Ohio

$7.69 ($0.26 / Count)

30+ Thompson Grape Seeds Vine Plant Sweet Excellent Flavored Green Grape

P Solves

$74.99 ($74.99 / Count)

Delirious Trembles Belgian Golden Strong Ale, Beer Making Extract Kit

Boomchugalug

$169.50 ($169.50 / Count)

Wine Ingredient Kit - CRU SELECT Australia Style Chardonnay

Bridgeview Beer and Wine Supply

$9.99 ($0.20 / Count)

CHUXAY GARDEN Mix Witch Finger Grape Seed 50 Seeds Grape Climber Vine Non-GMO Sweet Fruit Gardening High Yield Flourishing

color green

$155.96 ($155.96 / Count)

Winexpert Revelation Napa Cabernet Sauvignon 3 Gallon (Limited) Wine Ingredient Kit

Discount Hydroponics LLc

$29.99

Home Brew Ohio 6.5 Gallon Fermenting Bucket with Grommeted Lid and Three-Piece Airlock

Home Brew Ohio

AlFulchino

Winemaker of 30+ years

- Joined

- Jul 7, 2008

- Messages

- 3,035

- Reaction score

- 5

just reviewing this topic....how did/does the Schuco model #130 work out?

- Joined

- Nov 12, 2005

- Messages

- 15,188

- Reaction score

- 1,213

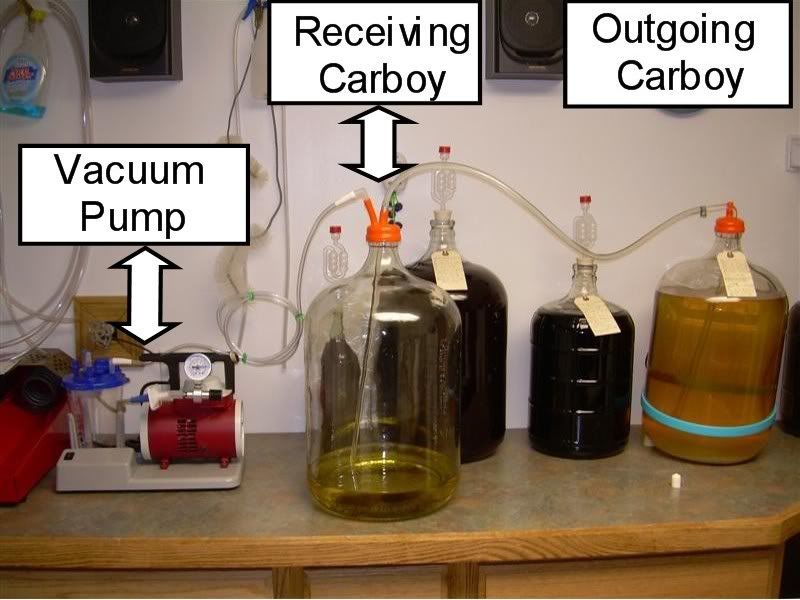

Mine is a different brand than that one, but same idea. Just remember Al that you need to rack into a carboy that can take vacuum. It transfers the wine, but you can't go into an open top container. They would well for all those 3 gallon carboys you bought.

Appleman is right. The vessel being racked from doesnt have to be able to hold a vacuum but the vessel being racked to does, at least to a small extent. I would think it could be a slightly collapsible container as you dont need to apply much vacuum to rack. I typically only turn my suction onto around 5-8" of vacuum to rack.

AlFulchino

Winemaker of 30+ years

- Joined

- Jul 7, 2008

- Messages

- 3,035

- Reaction score

- 5

wait a minute.....the vessel that the fluid is going 'into' has to be able to hold a vacuum? my early morning head is not grasping this

AlFulchino

Winemaker of 30+ years

- Joined

- Jul 7, 2008

- Messages

- 3,035

- Reaction score

- 5

i got ya....that set up doe snot look like it puts a huge vacuum pressure that will really pull on the glass...it is more a neutral thing since fluid is coming in and buttressing....my issue will be the flex tanks...i suspect they dont handle a negative pressure quite as well.....i think i am going to look more to a simple transfer pump...thanks for clearing that up for me Wade...the picture really helped

I think with for your volume you may want something a little more heavy duty but I think Rich uses the same thing and has no problem. It doesnt put much strain on the vessel during racking at all but yo do need a good seal to get it stated pulling or nothing will happen except youll just pull air.A March pump or even a dishwasher pump may be good for you as they are SS and food grade. You could check out Home brew supply store as they would carry a March pump, they are used totransfer hot liquids and are self priming I believe.

Again, I posted this before but just think about this. I also use a vacuum pump and it's great, convenient, and limits the exposure of air/wine. But remember.. these were aspirators and may have been subjected to less than clean air. The problem arise when you shut the pump "off". Any vacuum, anywhere will will equalize. You don't want atmospheric air entering the carboy via reverse through the pump. That will allow clean air to pass through the pump valves, pump oil, (yes all these pumps have oil in them and not mineral oil), and reverse through all the ports this aspirator has been subjected through it's entire life. You must think comfortably on how you want to handle the transfer after the vacuum. My suggestion is to install 2 ball valves (1 between the pump & receiving carboy, & 1 between the two carboys) this way you can stop the vacuum and re- pressurization via the pump. The other valve will allow you to stop drawing from the transfering carboy. This is helpful as when you even shut the vacuum, the transfer will continue for some time or until you have an equalized pressure. You want to stop transfer so you don't suck the transfer carboy dry and then pull in straight air and bubbles into your newly transfered carboy. Once you have your new carboy full, and if there is still a vacuum in it (which it will) the gasses in the wine will usually help if not completely equalize the carboy internal pressure, so now you can remove the the rubber stoppers and hoses. I forgot, I also have a small vacuum gauge inline also so I know the status of my carboy. My main reason again for this post is "Don't let the air from the pump return to your carboy!".

Okay, finally got my Buon Vino Automatic Auto Bottle Gravity Filler and hooked it up to my vacuum pump and bottled my Chilean Malbec. Took 3 bottles to get it set and am in love!!!!!!!!! I bottled this batch in about 5 minutes instead of 20 with the wand. For anyone with a vacuum pump I surely recommend this unit and Im sure it works as great without the pump. Just 1 more cheap tool that makes 1 of the not so fun parts of wine making better.

- Joined

- Nov 12, 2005

- Messages

- 15,188

- Reaction score

- 1,213

I'm glad you like it also Wade. When I'm in a hurry I just use the autosiphon and wand, and it ends up taking longer then the few minutes it takes to get the Buon Wino set up. It is even better when you have more to do. A couple hundred bottles goes much quicker with this setup.

I have missed this post for a while now somehow. Maghvac - the aspirator I have was a new never used one. It also has a built in guage and allows pressure regulation. When almost full or done, just back off on the vacuum to about 4 inches. When full or any air, just hit the switch and it stops. I then just pop the top which is easy with less than 5 inches vac.

The model I have is also an oilless model and never requires oiling. It also will run constantly for a half hour if need be with no heating up.

Al did you ever get set up with a transfer pump? There are many options available. You can set up with a Shurflo pump that transfers about 3 gallons a minute. You can get them in either 12 v dc or 120 ac. They are under a hundred bucks and with a prescreen filter, they will pump without problems. They are tapped for 1/2 inch so they aren't big, but will move a lot of wine.

I have missed this post for a while now somehow. Maghvac - the aspirator I have was a new never used one. It also has a built in guage and allows pressure regulation. When almost full or done, just back off on the vacuum to about 4 inches. When full or any air, just hit the switch and it stops. I then just pop the top which is easy with less than 5 inches vac.

The model I have is also an oilless model and never requires oiling. It also will run constantly for a half hour if need be with no heating up.

Al did you ever get set up with a transfer pump? There are many options available. You can set up with a Shurflo pump that transfers about 3 gallons a minute. You can get them in either 12 v dc or 120 ac. They are under a hundred bucks and with a prescreen filter, they will pump without problems. They are tapped for 1/2 inch so they aren't big, but will move a lot of wine.

AlFulchino

Winemaker of 30+ years

- Joined

- Jul 7, 2008

- Messages

- 3,035

- Reaction score

- 5

thanks Rich...i will google that...i was not happy w the one i purchased....it did not hold a prime to my satisfaction..gonna HAVE to be in a better position next season on this matter

Similar threads

- Replies

- 0

- Views

- 246

- Replies

- 23

- Views

- 11K